Back in February, I had the opportunity to tour the operations of JRE Tobacco Company. Run by tobacco industry icon Julio R. Eiroa and his son Justo, JRE Tobacco Company is a true vertical integrated crop to shop operation – ranging in everything from growing tobacco, processing tobacco, cigar production, and handling distribution. In this second installment, we talk through the process of growing and curing tobacco at the Corojo farm.

Let’s start our journey through the growing process at the very beginning with tobacco seeds. Tobacco seeds originate from the flowers of a tobacco plant. I observed several tobacco flowers draped in cheesecloth. This was done to protect the flower from insects.

The flower produces pods which contain tobacco seeds.

From there I saw the inception of the growing phase. This is where tobacco seedlings are grown. The Corojo farm has a nursery where this takes place.

Before walking into a nursery, one must undergo a foot rinse. This is a part of the Bayer CropScience program and it mitigates the chances of bacteria being introduced into the growing process.

[themify_box style=”light-green” ]

Bayer CropScience provides a series of best practices for agriculture and manufacturing. Many of these practices involve cleanliness. You see these practices in action the minute you arrive at the Corojo farm. This includes each person entering the farm walking through a disinfectant chamber, spraying down each vehicle entering the farm with disinfectant, and both hand and foot washes. These practices not only promote cleanliness, but one can also infer these help with improving the productivity and yield of the Corojo crop.

For more details on the Bayer CropScience Program be sure to see our Feature Story: Bayer CropScience a Daily Best Practice of Eiroa Operation

[/themify_box]

The seedlings stay in the nursery for about 38 to 42 days.

The seedlings are then planted in the fields. The Corojo farm leverages a drip irrigation system. As the name indicates, this system allows water and fertilizer to slowly drip to the roots of the tobacco plants. Over 400 acres of the Corojo farm has a drip irrigation system in place.

The use of such a system is more expensive than other means of irrigation, but, it allows the farm to use water and fertilizer more efficiently as well as deliver both more directly to the tobacco plant.

The tobacco plants grow and mature and eventually will yield seven primings (or 14 leaves)

As a general rule of thumb, the highest primings which have had the most exposure to the sun are going to be the most robust and flavorful. The lower primings are better for combustion of a finished hand-rolled cigar. The higher primings yield more flavor, but there is a tradeoff with combustion when used in the blend.

Once the tobacco leaves are harvested, they are taken over to the curing barns. The Corojo farm has 52 of these barns. These barns provide an environment to dry out the tobacco and regulate the temperature and humidity inside of them. The openings on the barn are used to facilitate this regulation.

The tobacco is taken inside the barn and strung up on racks and then raised up to dry. Approximately 44 leaves are put on each rack.

Video:

During the drying process, the leaves will release their moisture as well as the chlorophyll. This also results in the leaves turning brown in color.

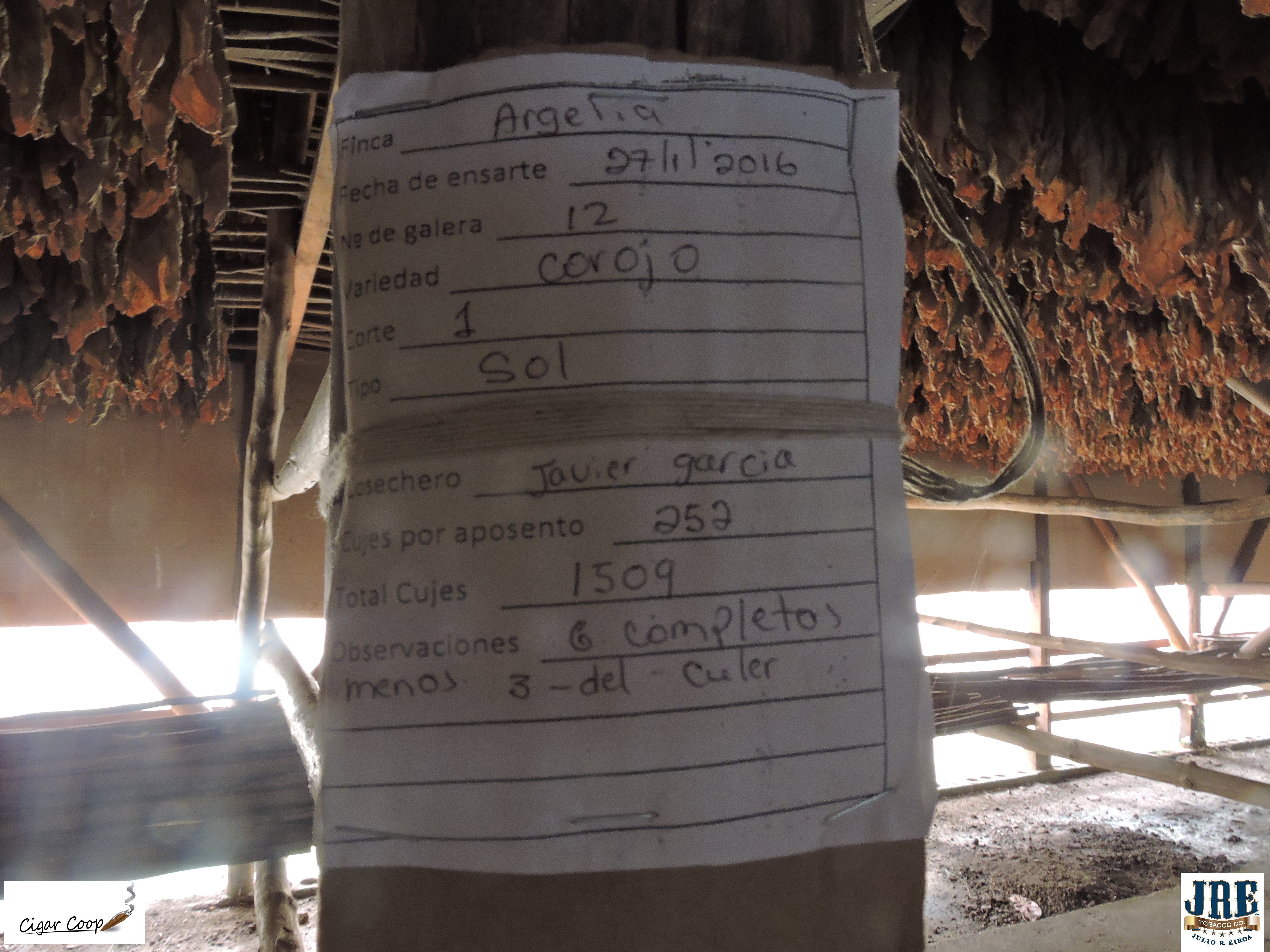

Data on the tobacco is kept and updated throughout the drying process. This data includes the farm, the type of the tobacco, who harvested the tobacco, how much tobacco, priming of the tobacco, and other notes. Tracking of the primings is something that the Eiroas are very cognitive of – especially as the tobacco moves into pre-production and production phases of cigar manufacturing.

Final Thoughts

In the first part of this series, I remarked on how the combination of processes and technology have helped give the Eiroa family an edge – particularly when being successful at cultivating Authentic Corojo tobacco. At the same time, there is still a lot of traditional aspects to the growing and cultivating of tobacco. As I revisited my notes and thoughts on this, it became clear that these traditional techniques were just as important as the innovation.

With Part 3 of this series (our next installment), we will turn our attention over to cigar production. We will see how the Eiroas use this combination of innovation and traditional techniques.

Part 1: A Visit to the JRE Tobacco Company Operations: Part 1-The Corojo Farm

Part 3: A Visit to the JRE Tobacco Company Operations: Part 3-The Factory Operations

Part 4: Meeting Mr. Eiroa

Also check out our special feature: Bayer CropScience a Daily Best Practice of Eiroa Operations

Photo Credits: Cigar Coop

January 14, 2018 @ 11:50 pm

Wow, dream farm